Sheeting and shoring are two key techniques in excavation that keep worksites safe, stable, and productive while digging is underway. These systems are designed to stop soil from collapsing, protect workers, and maintain steady ground conditions, especially when the site is deep or the soil is loose.

You’ll often see companies like In-Depth Excavation using these methods to handle everything from deep trenches to large foundation pits with confidence. Let’s take a closer look at what each method does, how they are different, and why picking the right system makes a big difference in keeping projects safe and on schedule.

What is Sheeting in Excavation?

Sheeting and shoring are two key techniques in excavation that keep worksites safe, stable, and productive while digging is underway. These systems are designed to stop soil from collapsing, protect workers, and maintain steady ground conditions, especially when the site is deep or the soil is loose.

You’ll often see companies like In-Depth Excavation using these methods to handle everything from deep trenches to large foundation pits with confidence. Let’s take a closer look at what each method does, how they are different, and why picking the right system makes a big difference in keeping projects safe and on schedule.

What is Shoring in Excavation?

Shoring provides structural support to an excavation site by using props or braces to reinforce the excavation walls. Think of shoring as the muscle behind keeping trench walls steady while work is underway. Unlike sheeting, which acts more like a barrier, shoring actively supports and stabilizes walls to keep them from moving or caving in.

Common shoring methods include hydraulic shoring, timber shoring, and steel frame systems. These systems are adjustable and can be customized to fit trenches and pits of various sizes and depths, making them vital for deep excavations, repairs near existing structures, or projects with unstable soil.

Differences Between Sheeting and Shoring

While sheeting and shoring are both designed to keep excavation sites safe, they serve slightly different roles. Sheeting is primarily about retaining soil, acting as a physical barrier to prevent collapse. Shoring, on the other hand, focuses on actively supporting the trench or excavation walls with props and braces. You might think of sheeting as the protective shield and shoring as the strong arms holding everything up. Sheeting is often used in shallower digs, while shoring is critical for deeper or more unstable sites.

Here’s a quick side-by-side breakdown:

Sheeting:

- Purpose: Retains soil and prevents collapse

- Materials: Wood planks, steel sheets, aluminum panels

- Best For: Shallow to medium-depth excavations

- Installation: Driven vertically along excavation walls

Shoring:

- Purpose: Provides active structural support

- Materials: Hydraulic jacks, steel braces, timber supports

- Best For: Deep excavations or unstable soil

- Installation: Props, frames, or hydraulic systems set up inside the excavation

By using both sheeting and shoring where appropriate, excavation teams can handle a wide variety of challenges, from preventing soil collapse to stabilizing deep trenches near sensitive infrastructure. This combination allows projects to move forward efficiently while protecting workers, surrounding structures, and the long-term integrity of the excavation site.

Types of Material Used for Sheeting and Shoring

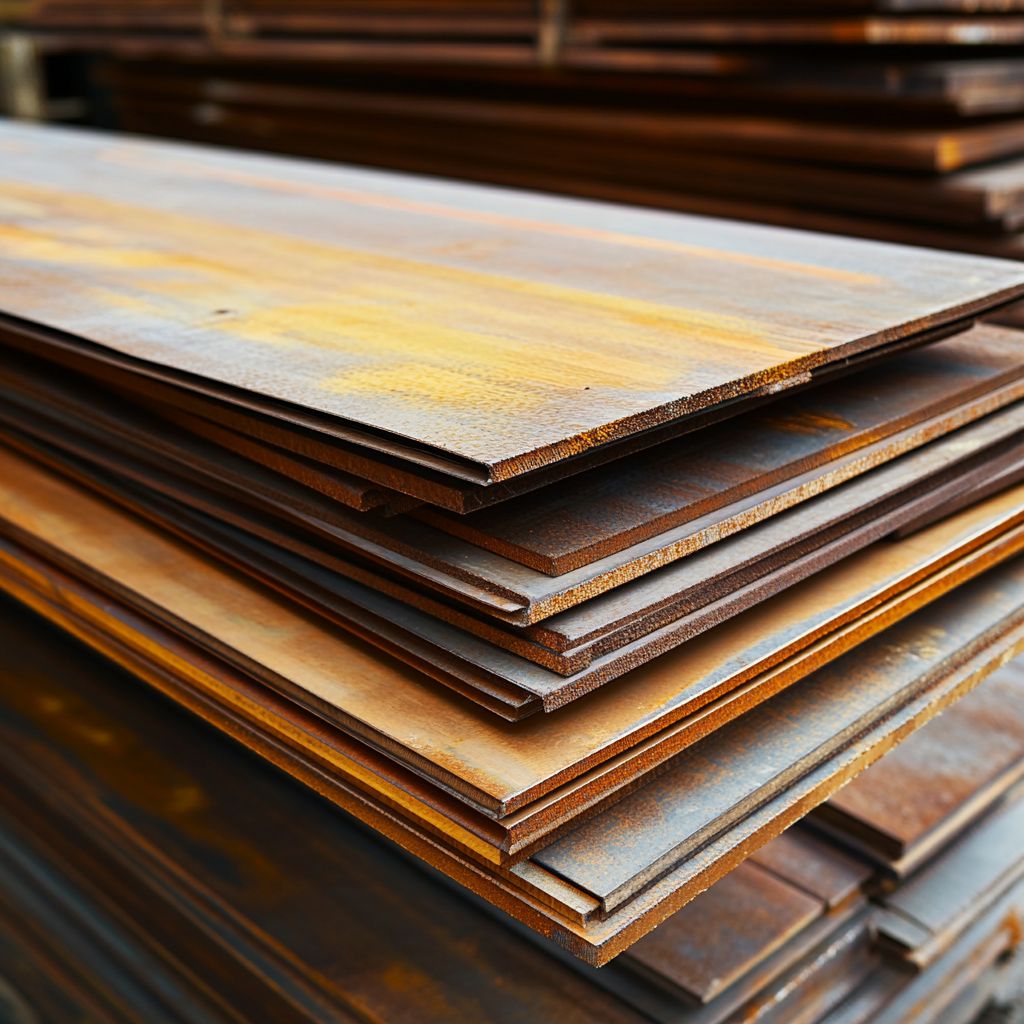

he materials chosen for sheeting and shoring can make a big difference in how effective and durable these systems are. Wood, steel, and aluminum are the most common materials, each suited for different site conditions and project demands.

Wood: Often used in the form of planks or boards, wood is a cost-effective option, especially for smaller or shallower excavations. It is easy to cut to size and install quickly, making it practical for short-term or temporary projects.

Steel: Steel sheets and supports are the go-to choice for deeper excavations or high-pressure soil conditions. Steel is strong, durable, and can handle wet or water-logged environments well. You’ll often see interlocking steel sheets used for retaining walls or deep trenching projects.

Aluminum: Lightweight and easy to handle, aluminum sheeting and shoring systems are often used in utility work and urban environments where space is tight and quick setup is important. Aluminum works best in small to medium-scale excavations where soil pressures are moderate.

The choice of material depends on factors like soil type, excavation depth, site access, and budget. Using the right material helps maintain safety, improves efficiency, and extends the life of the excavation support system.

Sheeting and shoring are vital tools in modern excavation, helping crews work safely and efficiently no matter the site conditions. By understanding the differences between these systems and selecting the right materials and methods, excavation teams can prevent accidents, protect surrounding structures, and keep projects on track.

Whether it’s a shallow trench or a deep foundation, having a solid sheeting and shoring plan is essential for success. Contact us today to learn how expert excavation services can make your next project safer and smoother.

FAQ on Sheeting and Shoring in Excavation

The main purpose of sheeting in excavation is to provide temporary support to the walls of an excavation site, preventing soil movements and collapses. It involves driving large, flat sheets of material, such as wood, steel, or aluminum, into the ground to form a continuous wall that holds the earth in place.

Shoring is used to support structures, trenches, or excavations at risk of collapse, primarily through the use of props or supports like hydraulic jacks, posts, or mechanical systems. While sheeting is used for soil retention, shoring is more focused on providing structural support.

Sheeting is often employed in deep excavations, such as for building basements or underground facilities. Shoring is commonly used in trench excavations, infrastructure repairs, and in situations where temporary structural support is necessary.

Common materials for sheeting and shoring include wood, steel, and aluminum. The choice of material depends on the project’s specific requirements, soil conditions, and the depth of the excavation.

Yes, there are several methods of shoring, including hydraulic shoring, beam and plate shoring, and slide rail shoring. Each method has its own advantages and is selected based on the project’s needs and the conditions of the excavation site.

- Yes, the soil type can significantly influence the choice and application of sheeting and shoring techniques. Softer soils may require more robust support systems, while stable, rocky soils might need less intensive methods.

While not all excavation projects may require sheeting and shoring, they are essential for projects involving deep excavations, unstable soil, or when working near existing structures. Safety is the primary concern, and these techniques are employed to ensure the stability and safety of the excavation site.

In-Depth Excavation, with over 60 years of combined experience in the field, ensures the effectiveness of sheeting and shoring by conducting thorough site assessments, using high-quality materials, and employing skilled professionals to implement these techniques as per project requirements.