Breaking concrete is a key task in many excavation projects. This guide provides an overview of various methods and tools, tailored to different scenarios in the field of excavation.

Hydraulic Breakers: Power and Efficiency for Large-scale Projects

Hydraulic breakers are formidable tools in the world of excavation. Attached to the arm of an excavator, they use hydraulic power to deliver powerful, repetitive blows, capable of breaking even the thickest concrete. Ideal for large-scale demolition projects, these breakers reduce manual labor and save time. However, their power demands skilled operation and careful handling. They may not be the best choice for projects requiring delicate precision.

Pros:

- Highly effective for large-scale demolition.

- Saves time and reduces manual labor.

Cons:

- Requires skilled operation.

- Not suitable for precision work.

Excavator Mounted Jackhammers: Precision in Demolition

A more precise alternative to hydraulic breakers, excavator-mounted jackhammers offer a balance between power and precision. They are particularly useful in urban areas or sites where minimizing collateral damage is crucial. While not as powerful as hydraulic breakers, they provide more control, making them suitable for projects that require careful dismantling rather than outright demolition.

Pros:

- More control and precision.

- Suitable for urban and sensitive areas.

Cons:

- Less powerful than hydraulic breakers.

- Slower in large-scale demolition.

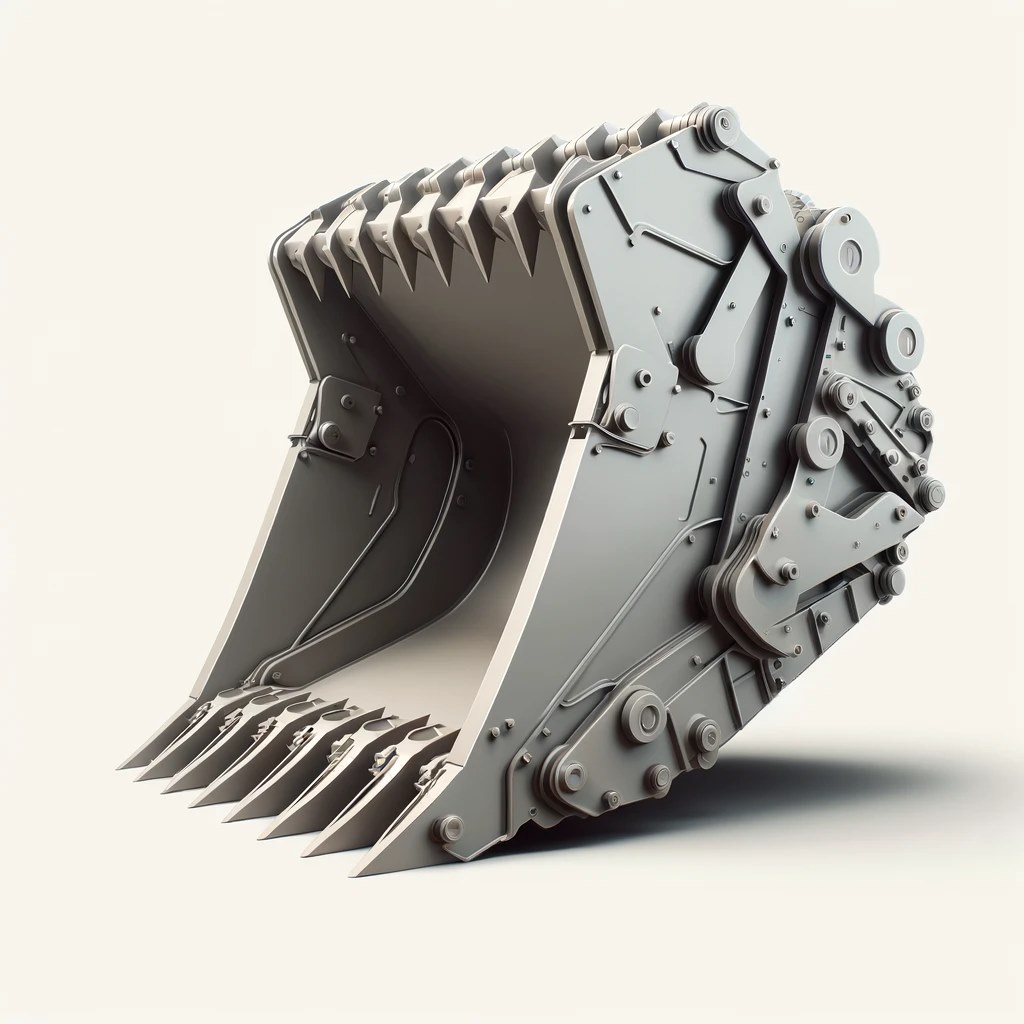

Bucket Crushers: Efficient Debris Management

Bucket crushers are unique attachments that crush concrete into smaller pieces. This process is particularly beneficial for managing debris and preparing it for disposal or recycling. While efficient for smaller structures, bucket crushers may struggle with very thick or reinforced concrete, limiting their use to medium-scale projects.

Pros:

- Effective for concrete recycling.

- Manages debris efficiently.

Cons:

- Struggles with very thick or reinforced concrete.

- Limited to medium-scale projects.

Ripper Attachments: Tearing Through Reinforced Concrete

Rippers are designed to tear through concrete and are particularly effective against layered structures or reinforced concrete. The sharp, robust design allows them to handle challenging materials that other attachments might struggle with. However, their aggressive nature requires experienced operators to prevent unnecessary damage to surrounding areas.

Pros:

- Effective against reinforced and layered concrete.

- Handles tough materials.

Cons:

- Requires experienced operation.

- Potentially damaging to surrounding areas.

Handheld Jackhammers: Portable and Practical

For smaller jobs or precise demolition work, handheld jackhammers are the tools of choice. These portable tools are perfect for residential renovation projects or areas where larger machinery cannot reach. While affordable and easy to use, they require significant physical effort and are not suitable for breaking large or thick slabs of concrete.

Pros:

- Portable and user-friendly.

- Ideal for small, precise tasks.

Cons:

- Labor-intensive for large jobs.

- Ineffective for thick concrete.

Concrete Saws: Precision Cutting

Concrete saws, available in various types like handheld and walk-behind models, are used for precise cutting rather than outright breaking. They are ideal for creating clean edges, shapes, or preparing for controlled demolition. While they offer precision, the creation of dust and the limitation to cutting rather than breaking are factors to consider.

Pros:

- Precise cutting capabilities.

- Suitable for detailed work.

Cons:

- Limited to cutting, not breaking.

- Creates dust.

Sledgehammers: The Traditional Approach

For quick, small-scale tasks, the traditional sledgehammer can be an effective tool. Requiring no power source and being relatively inexpensive, they are a practical choice for minor concrete breaking tasks. However, the physical effort and time required make them impractical for larger projects.

Pros:

- Simple and cost-effective.

- No power source is needed.

Cons:

- Physically demanding.

- Inefficient for large or thick concrete.

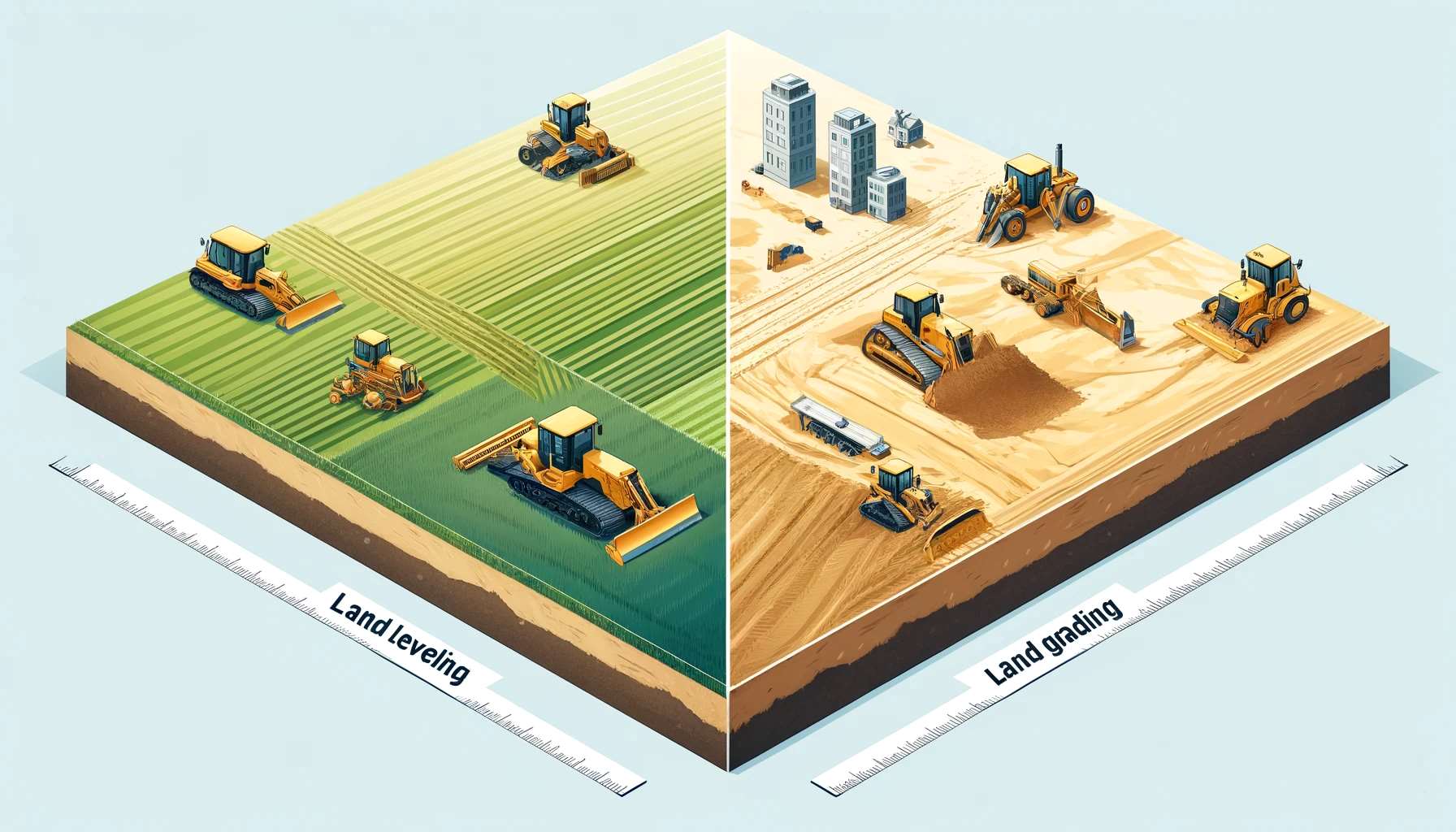

Ranking Concrete Breaking Methods: Ease, Difficulty, and Time Consumption

Ease of Use: Simplifying Your Choice

When it comes to ease of use, it’s not just about the tool but also the skill required. On one end of the spectrum, we have Sledgehammers, requiring no technical skill and offering straightforward operation. This simplicity is closely followed by Handheld Jackhammers, which, while user-friendly, demand a bit more labor. As we move up the scale, Concrete Saws come into play, needing technical skill for precision, but still quite manageable.

For those comfortable with excavator operation, Bucket Crushers and excavator-mounted jackhammers provide a moderate challenge, demanding skill and control. At the higher end of the scale are Hydraulic Breakers and Ripper Attachments – powerful and efficient, yet requiring a high level of skill and precision, making them more challenging to operate.

Difficulty: Tackling the Tough Jobs

If we’re talking about the level of difficulty, it’s a different ball game. Sledgehammers are your go-to for small, straightforward tasks, but as the scale and complexity of the job increase, so does the difficulty of the tool you might need. Handheld Jackhammers can tackle more demanding jobs, but they remain within the manageable range for small-scale projects.

With Concrete Saws, you’re stepping into the realm of precision work, which brings its own set of challenges. Bucket Crushers require adept maneuvering, while excavator-mounted jackhammers demand a balance of power and precision, adding to their complexity. For the more formidable tasks, Hydraulic Breakers and Ripper Attachments stand at the top of the difficulty ladder, best suited for those who can handle their power and intricacies.

Time Consumption: Balancing Speed and Efficiency

In terms of time efficiency, different tools cater to different space requirements. For rapid action in large-scale demolition, Hydraulic Breakers are the undisputed leaders, swiftly breaking through large concrete structures. Close on their heels are Ripper Attachments, quick and effective but requiring a bit more finesse.

Excavator Mounted Jackhammers and Bucket Crushers find a middle ground, offering efficiency but at a slightly slower pace compared to the heavy hitters. Concrete Saws have a variable time factor, heavily dependent on the precision required for the task. On the slower end, we have Handheld Jackhammers, best for smaller areas, and finally, Sledgehammers, which, while straightforward, can be the most time-consuming due to the sheer manual effort involved.

Conclusion

Selecting the right method for breaking concrete is crucial for both efficiency and safety in excavation projects. This guide offers insights into the various tools and methods available, helping you choose the most appropriate one for your specific needs. Remember, professional advice and services are invaluable for complex or large-scale projects.

Just so happens We’re professionals and we will give you free quotes on whatever job you need! Contact us At In-depth today, Rock & Stone won’t stop our goals for your hole!

Looking for a Demolition Contractor In Snohomish County, WA? No matter the job, we can do it!

FAQs on Concrete Breaking Methods in Excavation

The most user-friendly methods are sledgehammers and handheld jackhammers. Sledgehammers require no technical skill and are great for small tasks, while handheld jackhammers are slightly more labor-intensive but still manageable for small to medium projects.

Hydraulic breakers are the fastest for large-scale demolition. They are powerful and efficient, ideal for quickly breaking through large and thick concrete structures.

Concrete saws are primarily used for precise cutting, not for complete demolition. They are perfect for creating clean edges or preparing for controlled demolition but are not suitable for breaking down entire structures.

For precision demolition work, excavator-mounted jackhammers are a great choice. They offer a balance between power and precision and are particularly useful in urban areas or sites where minimizing collateral damage is important.

Ripper attachments are particularly effective for breaking reinforced concrete. They are designed to tear through tough materials, including reinforced concrete layers, but require skilled operation to prevent unnecessary damage.